Concrete Mixer is a kind of multifunctional machinery which combines the transit mixer, concrete mixer and Wheel Loader together. It can automatically load, measure, mix and discharge concrete mixture. the self loading concrete mixer is just like a truck and the operator can drive it to where it needs to go. It is very convenient for loading material, such as cement, aggregate, stone. The mixing unit is slewing hydraulically through 290° for high discharge over 2 m on the four sides of the vehicle. Used Concrete Mixer Truck,Concrete Mixer Truck,Cement Mixer,Mini Mixer Truck Shandong Nuoman Engineering Machinery Co., Ltd , https://www.chinanuoman.com

The wide cabin windscreen and the specially designed loading arms dramatically improve visibility during casting operations. This high-productivity self loading concrete mixer easy to use, features excellent daily performance and reliability. Thanks to these characteristics, it is the ideal solution for rental purposes and for maintenance operations.

We’re thrilled to share some exciting updates for the Netfabb community this year. As part of our ongoing effort to enhance design, engineering, and manufacturing capabilities, we’re integrating Netfabb tools into the Autodesk Fusion 360 ecosystem. This means that all Netfabb subscribers will continue to enjoy their existing tools while gaining access to the full range of Fusion 360 features—everything from 3D modeling and simulation to documentation and manufacturing support.

For many users, this new offering includes the Additive Build Extension and the upcoming Additive Simulation Extension at no extra cost. Additionally, you’ll gain access to Fusion 360 Team and HSMWorks, which will further streamline your workflow and collaboration with others.

Building on the unified Fusion 360 and PowerMill solutions announced in August, this update ensures that you get more functionality for the same price. All Netfabb subscriptions now include Fusion 360, and Premium and Ultimate subscribers will also receive the Additive Build Extension to help set up metal additive manufacturing jobs. Ultimate users will automatically get the future Additive Simulation Extension as it becomes available.

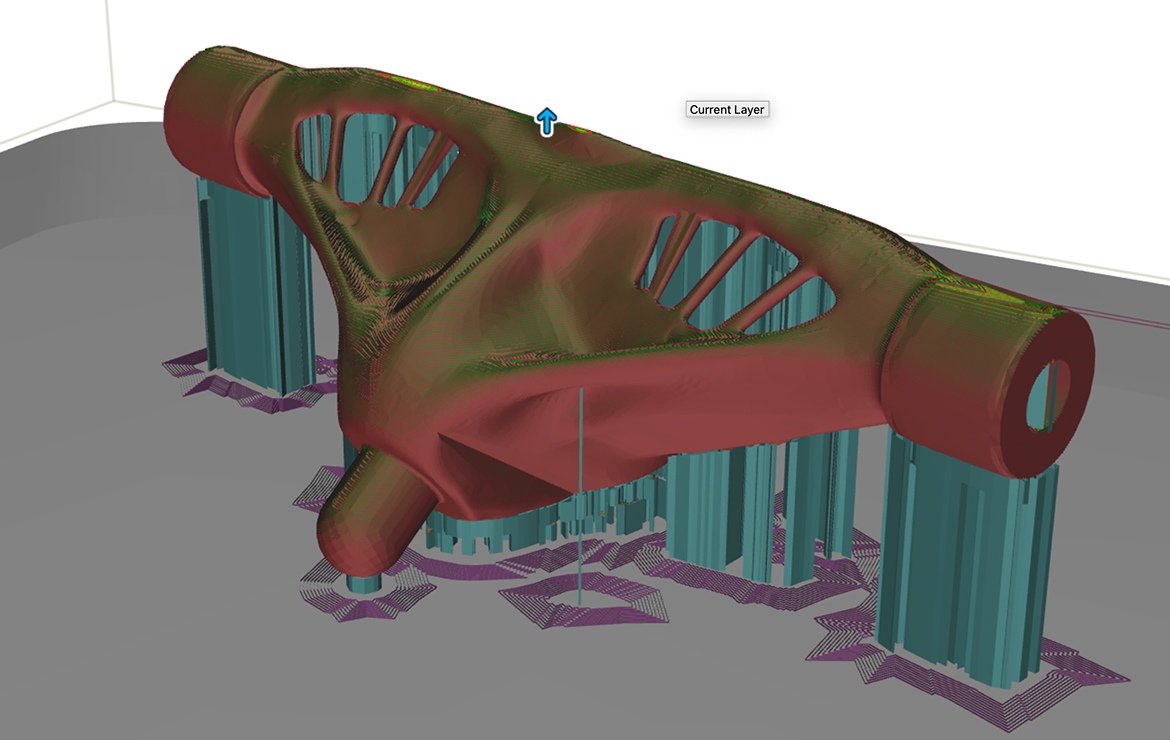

*Generatively designed skateboard truck made for Braille Skateboarding, with print prep completed in Fusion 360.*

This move reflects our commitment to future-proofing your design and manufacturing workflows. Our goal is to empower you to work more efficiently and gain a competitive edge by leveraging advanced tools in one integrated platform.

Fusion 360 extensions bring powerful new capabilities to both designers and manufacturers. For example, the Additive Build Extension, launched in October, introduces metal powder bed fusion functionality along with intelligent orientation and support structure generation. Soon, we’ll be launching the Additive Simulation Extension, allowing users to run simulations before printing to identify potential issues early on.

More details about recent and upcoming extensions can be found in this announcement from Autodesk University.

Collaboration between designers, engineers, and fabricators has always been a core part of Autodesk’s vision. We're continuously improving connected workflows, automating processes, and enabling better supply chain integration. Fusion 360 serves as a single, unified platform that uses one data model to eliminate file conversion delays, loss of detail, and rework. Our aim is to make it easier for users to bring their ideas to life, experiment with new tools like the Generative Design Extension, and achieve their creative visions smoothly.

*Skateboard truck manufactured with DMLS titanium. Photo courtesy of Troy Young.*

“Additive manufacturing is one of the most transformative technologies in the industry,†said Sualp Ozel, Senior Product Manager for additive technologies in Fusion 360. “It offers benefits like faster time-to-market, lighter products, and less waste. At Autodesk, we’re focused on removing barriers that slow down design and manufacturing, making the entire process seamless within a single toolset. This change gives our users the right tools to develop and manufacture innovative products.â€

*3D-printed, generatively designed skateboard truck in use by Braille Skateboarding. Photo courtesy of Troy Young.*

If you’d like to learn more about Netfabb, visit [this page](#). For details on Fusion 360, check out [our site](#).

*Note: Statements regarding planned or future product developments are not guarantees but reflect current plans based on known factors. Purchasing decisions should not rely solely on these statements.*