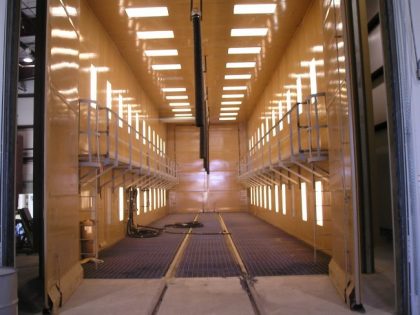

The term "turnkey" has become increasingly popular across various industries—from real estate to technology and manufacturing. It refers to a complete solution that is ready to use upon delivery, much like a house with a key in the door. However, not all turnkey solutions are created equal. In industrial settings, especially in metal finishing, a true turnkey installation involves a full-service approach that covers everything from planning and design to final installation and compliance checks. In the context of industrial installation services, a turnkey project is more than just a pre-packaged option. It’s a comprehensive process that includes detailed project analysis, custom engineering, manufacturing, installation, and ongoing support. For businesses looking for a reliable partner in metal finishing, choosing a single provider that offers turnkey solutions can streamline operations and ensure a smooth experience from start to finish. Finishing Systems has delivered numerous successful turnkey installations, including Abrasive Blast Rooms, Custom Paint Booths, Air Make-Up Systems, and Powder Coating Units with Process Control Ovens. Whether you're setting up a new facility or upgrading an existing one, we offer tailored solutions designed to meet your specific needs. Our goal is to provide you with a professional, efficient, and long-lasting installation that supports your business goals. Contact Us Turnkey installation services bring significant value to businesses in the metal finishing industry. With experienced project managers who maintain clear communication throughout the entire process, we ensure that every stage—from initial design to final installation—is handled efficiently and effectively. Here are some of the key advantages of opting for a turnkey installation: At Finishing Systems, we specialize in delivering customized turnkey solutions that match your unique requirements. Here are some of the services we provide: For over 40 years, Finishing Systems has been a trusted name in the metal finishing industry. We combine technical expertise with exceptional customer service to deliver innovative and reliable solutions for businesses of all sizes. When you choose us for your turnkey installation, you gain a dedicated partner committed to your success. Our single-contact project management system ensures that your project is handled seamlessly from start to finish. We take pride in our attention to detail, ensuring that every step of the process is executed with precision and care. We understand that every business has unique needs, and we tailor our solutions accordingly. From initial consultation to final installation, we handle everything so you don’t have to worry about missing steps or delays. Our team is here to support you every step of the way, providing peace of mind and confidence in your investment. At Finishing Systems, we treat every client like family. Your satisfaction is our top priority, and we go above and beyond to ensure that your project is completed on time, within budget, and to your complete satisfaction. With over four decades of experience, Finishing Systems continues to set the standard for excellence in industrial finishing equipment and turnkey installation services. No matter the size of your project, we are here to help you achieve your goals with precision, professionalism, and personalized service. Don’t miss out on the benefits of a true turnkey installation. Contact us today to learn more about how we can support your next project and provide the best possible solution for your business. Contact Us Today Single Or Multiple Rotor Air Classifier

â—† Fine chemicals, ceramics, abrasions and refractorials] Typical materials are: garnet silicon carbide, corundum, cerium oxide, alumina, boron carbide, tungsten carbide, emery, etc.

â—† Food, medicine and health care products] Typical materials are: pollen, hawthorn, pearl powder, stomach medicine, nimodipine, antibiotics, contrast drugs, Ganoderma lucidum, Gallnut, multiflorum multiflorum, etc. :

â—† Magnetic powder, mobile phone electromagnetic powder, photocopying toner and electronic materials Typical materials are: lead battery, nickel-chromium battery, nickel-manganese battery, ferrite, manganese tetroxide, manganese dioxide, lithium cobalt, lithium manganate, carbon, etc.

â—† Non-metallic ore and powder metallurgy] Typical materials are: quartz, barite, kaolinite, high calcium, talc, mica, graphite, wollastonite, etc.

â—† Reflective materials, pigments, dyes and powder coatings] Typical materials are: iron oxide, titanium dioxide, glass beads, etc. :

â—† Pesticide, feed and biological materials

Air Classifier,single rotor air classifier,double rotor air classifier fine chemicals,ceramics,Abrasions air classifier Shandong Jing Xin Powder Equipment Technology Co., Ltd. , https://www.jxpowder.com

Understanding the Benefits of Turnkey Installation

Updated: December 22, 2023

BENEFITS OF TURNKEY INSTALLATION

SERVICES WE OFFER WITH TURNKEY INSTALLATION

WHY CHOOSE FINISHING SYSTEMS?

GET IN TOUCH TODAY