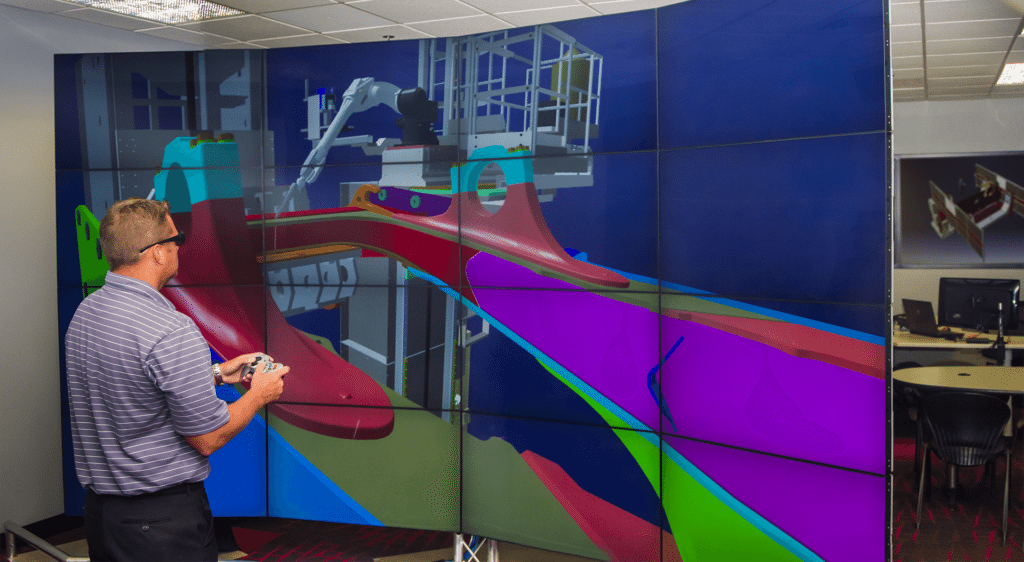

For quite some time now, virtual solutions for robot simulation have existed, though they haven't always been widely embraced. Back in the 1980s, when robots were scarce and incredibly costly, simulation was a common practice among research groups. These groups relied heavily on virtual models to plan, test, and refine their robotic systems. However, things changed in the 1990s. As robots became more affordable and accessible, research teams began shifting their focus toward hands-on experimentation with physical robots. This shift temporarily sidelined the use of simulations, as researchers sought to validate their ideas through real-world testing. But as we’ve seen in recent years, advancements in computational power have reignited interest in simulation tools within the private sector. This renewed emphasis on virtual solutions represents a significant milestone in the field of robotic automation. By providing a safe, cost-effective way to explore complex scenarios, these tools empower engineers to innovate without the risks associated with direct experimentation. However, before diving deeper into why this trend matters, let's take a closer look at what virtual solutions centers actually do and how they function. As part of certain robotics systems integrators' offerings, Virtual Solutions Centers aim to create comprehensive digital replicas of entire robotic systems and their operational environments. These simulations account for every conceivable variable involved in the process, allowing integrators to demonstrate proof-of-concept scenarios. By meticulously recreating real-world applications, these centers ensure that the final product aligns closely with client expectations. Often, the programming used in the simulation can be seamlessly transferred to the actual hardware once deployment begins, streamlining the transition from concept to implementation. Vital to the success of robotic integration projects, Virtual Solutions Centers play several crucial roles. Foremost among them is the ability to confirm feasibility prior to any physical construction taking place. This precautionary step helps prevent costly mistakes by identifying potential design flaws early on and verifying that productivity targets will indeed be met. Beyond just ensuring accuracy, these centers enable integrators to push boundaries by exploring novel technologies safely within a controlled virtual setting. Additionally, simulations reduce barriers to entry for businesses considering investments in automation, making advanced robotics more accessible than ever before. Such developments not only enhance current practices but also foster growth across the broader robotics landscape. The adoption of Virtual Solutions Centers marks an exciting chapter in the evolution of industrial robotics. Both manufacturers and integrators reap substantial benefits from leveraging sophisticated simulation software, driving efficiency gains while lowering overall project costs. If you'd like to delve further into specific case studies showcasing the power of robot simulations, consider checking out Genesis’ dedicated page on their Virtual Solutions Center. There, you'll find detailed examples illustrating how these tools contribute to smarter manufacturing processes worldwide. A Gas Pizza Oven is a versatile and efficient appliance, perfect for creating restaurant-quality pizzas in the comfort of your home or in a professional kitchen. Unlike traditional wood-fired or electric ovens, gas pizza ovens offer the advantage of precise temperature control and quicker heat-up times, making them a favorite among both amateur chefs and professional pizzaiolos. Constructed from high-quality stainless steel, gas pizza ovens are designed to withstand high temperatures and frequent use. The interior is often lined with heat-retaining materials such as ceramic or refractory stone, which ensures even heat distribution and a consistently crispy crust. The gas burners, strategically placed, provide uniform heat across the baking surface, eliminating the need for constant rotation of the pizza. One of the standout features of a gas pizza oven is its convenience. With just a turn of a knob, you can achieve the high temperatures necessary for baking a perfect pizza in mere minutes. This speed and efficiency make it ideal for busy kitchens where time is of the essence. Additionally, gas ovens are typically easier to clean than their wood-fired counterparts, as there is no ash or soot to manage. Gas pizza ovens are also celebrated for their versatility. Beyond pizzas, they can be used to bake bread, roast vegetables, and even cook meats, offering a wide range of culinary possibilities. Many models come equipped with additional features such as built-in thermometers, adjustable racks, and even rotisserie attachments. Whether you're hosting a pizza party in your backyard or running a bustling pizzeria, a gas pizza oven delivers consistent, high-quality results with the added benefits of convenience and control. It brings the authentic taste and experience of a traditional pizzeria into any setting, making it an indispensable tool for any pizza enthusiast. Gas Pizza Oven,outdoor Gas Pizza Oven,Gas Pizza Oven bbq,bbq gas pizza oven gftop , https://www.gftopgrill.comVirtual Solutions Center: The Role of Robot Simulation in Enhancing Robot Integration

What Are Virtual Solutions Centers and How Do They Operate?

Why Are Virtual Solutions Centers Significant?

I thoroughly enjoyed reading your explanation regarding the importance of virtual solutions for robot simulations. Your insights shed light on both technical aspects and practical applications, which are invaluable for anyone looking to stay informed about modern robotics trends. Kudos!