Heavy lift drones are known for their unique ability to carry heavy payloads in the air, far beyond what regular drones can handle. These large drones, capable of carrying up to 500 kg, are ideal for missions that require transporting big loads—like high-quality LiDAR systems, large sensors, or bulk cargo. The performance of these drones heavily depends on one key component: the electric motors. Whether you're an engineer working with drone technology or just someone interested in how heavy lift drones work, this article is for you. We'll cover everything from the definition of heavy lift drone motors to their types, key parameters, and how to choose the right motor for your needs. Let's dive in! A heavy lift drone motor is the propulsion system used in drones designed for lifting heavy payloads. These motors are more powerful and robust compared to those found in standard consumer drones, as they need to provide enough thrust to carry substantial weights. Heavy lift drones are widely used in industries such as agriculture, construction, cinematography, and logistics, where transporting large loads is essential. Brushless motors for PH-20 heavy lift multi-rotor UAVs Heavy lift drones commonly use high-powered brushless motors, designed to deliver substantial thrust and lifting capacity for handling hefty payloads. Take the PH-20 heavy-lift multirotor drone, equipped with a robust combination of bus ESC, a high-efficiency brushless motor, and a high-performance propeller. Crafted for power and efficiency, the PH-20 excels in challenging conditions, accommodating up to 10kg loads with an impressive endurance of up to 70 minutes. Motors used in heavy lift drones, particularly those designed for large payloads, commonly leverage electric brushless DC motors. These motors are preferred over brushed motors due to their higher efficiency. In a brushless motor, the transfer of current from the commutator to the rotor occurs through non-contact methods, reducing energy losses associated with friction. Rotor and Stator of an Outrunner Electric Motor. Source from tytorobotics.com Key features and enhancements: 1. Integrated Centrifugal Fans: Some high-thrust motors incorporate integrated centrifugal fans to enhance cooling. Efficient cooling is crucial to prevent overheating during prolonged heavy lift operations. 2. High-Temperature Solid Core Copper Windings: The use of high-temperature solid core copper windings contributes to the motor's ability to handle elevated temperatures, which can be a concern during demanding drone operations. 3. Angular-Contact and Radial-Contact Ball Bearings: Motors designed for heavy lift applications may include angular-contact and radial-contact ball bearings. These bearings improve the overall durability and efficiency of the motor. Brushless heavy-lift drone motors often adopt an "outrunner" design. In this configuration, the rotor rotates outside the stator, as opposed to within it. This design choice increases the torque generated by extending the application diameter. The larger diameter over which forces are applied results in greater torque, making these motors well-suited for heavy lift requirements. In addition to brushless motors, some heavy-lift drones incorporate a unique counter-rotating motor setup to further enhance efficiency. Key elements of counter-rotating motors: 1. Slip Ring Mechanism: The counter-rotating motor setup employs a slip ring mechanism. This mechanism allows the capture of energy from both the active and reactive forces generated by the spinning motor. 2. Energy Harnessing: The energy from the reactive counter-force, typically absorbed by the non-moving stator and the body of the UAV, is harnessed. This harvested energy is then redirected to drive a counter-rotating propeller on the same motor. The counter-rotating setup results in greater overall efficiency compared to standard motors. By effectively utilizing both the active and reactive forces, these motors can contribute to improved thrust and lift capabilities, making them particularly suitable for heavy-lift drone applications where maximizing efficiency is crucial. Choosing the right motors for a heavy lift drone is a critical decision that directly impacts the drone's performance, stability, and efficiency. Here are key considerations to keep in mind: To begin building a drone, start by calculating its weight, factoring in components such as the frame, flight controller, ESCs, motors, propellers, battery, camera, and antenna. Add a 10-20% buffer to account for potential inaccuracies or future modifications. Once you have the estimated drone weight, determine the frame size. Ideally, the frame should accommodate a maximum propeller size equal to one-third of its dimensions. This proportionality optimizes aerodynamic performance, striking a balance between lift and stability for efficient flight. Drone frame. Source from unsplash.com Once you have determined the estimated weight of your drone and selected an appropriate frame size, the next crucial step in the design process is to establish the thrust requirements. A fundamental guideline to follow is that the combined maximum thrust generated by all the motors should be at least double the weight of the drone. For instance, if your drone weighs 1 kilogram, the collective thrust from all the motors should be a minimum of 2 kilograms. In the case of a quadcopter, this translates to each motor producing a maximum thrust of at least 500 grams. This threshold ensures that the drone has the lifting capacity required for takeoff. Ideally, for standard drones, a thrust-to-weight ratio of 3:1 or 4:1 is recommended. This ratio ensures that the drone not only lifts off effectively but also possesses the maneuverability needed for smooth and controlled flight. Additionally, it allows the drone to accommodate extra payloads without compromising its overall performance. PH-20 with MG-130E gimbal camera for aerial surveillance A drone motor, whether brushed or brushless, consists of a stator with metal coils and a motor bell housing permanent magnets. The stator's width and height, denoted by XXYY, determine the motor size. Larger motors offer more torque and thrust but are less responsive and heavier. The metal coils, enameled for insulation, form the stator and generate a temporary magnetic field when an electric current flows through them. The motor bell, attached to the inner side of the motor, protects the permanent magnets and coils. The motor shaft transfers torque from the motor to the propellers when the changing magnetic fields cause rotation. Choosing the right motor size is critical. Larger motors provide more thrust but sacrifice responsiveness and add weight. For multi-copters, determining the required thrust from each motor based on a desired thrust-to-weight ratio is essential. This ensures optimal performance by listing motors meeting the thrust requirement and selecting the smallest ones that fulfill these specifications, balancing power, responsiveness, and weight for efficient drone functionality. When selecting BLDC motors for drones, their dimensions—specifically, stator width and height—play a crucial role in performance. Wider stator motors have greater inertia, making them less responsive to speed changes but offering effective cooling due to increased surface area. Additionally, their design allows for larger bearings, enhancing durability, efficiency, and stability. Narrow stator motors are more responsive but may face challenges in cooling due to their compact design. The choice between wide and narrow stators hinges on the drone's purpose. For drones lifting payloads, where responsiveness is less critical, wider motors are preferred. Payload drones require careful piloting, making the sacrifice in responsiveness acceptable for the benefits of cooling efficiency and motor robustness. An electric motor with all its copper windings. Source from unsplash.com The next critical step is to consider the relationship between KV ratings and propeller selection for optimal drone performance. Higher KV ratings indicate more revolutions per minute (RPM) when one volt is applied to an unloaded motor. Motors with higher KV ratings typically have shorter windings and lower internal resistance, but they are prone to early heating. This heating issue is more evident in taller motors with higher KV ratings due to their greater rotational speeds and thrust generation. The conventional strategy involves pairing motors with higher KV ratings with lighter propellers and motors with lower KV ratings with heavier propellers. This approach ensures a balance between motor characteristics and propeller load. When a high KV rating motor is combined with a heavy propeller, it attempts to rotate the propeller at maximum speed, requiring more torque and drawing increased current. This situation could potentially damage the Electronic Speed Controller (ESC) or MOSFETs. Conversely, a low KV rating motor paired with a lighter propeller may struggle to produce sufficient thrust. For those opting for wider motors to enhance maneuverability at slower speeds, a low KV rating motor with heavier propellers is recommended. Conversely, for drones focused on rapid racing without carrying a payload, choosing a taller motor with a high KV rating and lighter propellers is more suitable. It's crucial to note that the KV rating is a manufacturer-provided estimate, and actual motor RPM may vary due to factors like air resistance. Whether selecting a low KV rating motor with a heavier propeller or a high KV rating motor with a lighter propeller, the key is to achieve the desired thrust-to-weight ratio. The torque a motor produces relies on factors like stator volume, magnet types, coil quality, and construction details (e.g., pole count, insulation gap). Greater stator volume generally means a heavier motor, but if two motors share the same stator volume, the lighter one is preferred. Motor torque affects responsiveness to pilot input. Excessive torque can lead to jerky drone movements, causing difficulties in control and potential damage to the ESC unit due to voltage or current surges. Choosing a lighter motor strikes a balance between power and control, mitigating these issues. For optimal performance, selecting motors tailored to specific needs is crucial. In scenarios where slow, steady flight with a payload is required, opting for motors with lower torque and RPM is recommended. This ensures a precise and controlled flight experience while safeguarding electronic components. The torque constant of a drone motor dictates the current required to generate torque. Although not theoretically linked, practical observations reveal a trend: higher KV rating motors generally have higher torque constants, while lower KV rating motors have lower torque constants. In practice, this means high KV rating motors draw more current to achieve a given torque, impacting energy efficiency. High KV rating motors are less power-efficient than their low KV rating counterparts due to increased current consumption. Optimal power efficiency requires choosing a KV rating that balances performance and efficiency, preventing excessive torque constant that hampers overall effectiveness. Utilizing a motor with an excessively high torque constant poses risks, including damage to the Electronic Speed Controller (ESC) and motor heating issues. Long-term consequences include reduced battery lifespan and increased wear on wires, motors, and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors). Selecting a suitable Brushless DC (BLDC) motor for a drone hinges on careful evaluation of voltage and current ratings. The relationship between motor voltage and current draw is crucial—higher motor voltage typically results in increased current consumption from the battery during operation. To determine the maximum current drawn by the motor, calculate this value when the motor operates at its highest voltage, generating maximum thrust. This calculation is pivotal for selecting an Electronic Speed Controller (ESC) with an appropriate current rating. When choosing an ESC, ensure that its current rating surpasses the maximum current drawn by the motor. While the continuous current rating of the ESC is important, it does not necessarily need to exceed the maximum motor current. However, it's imperative that the burst current rating is greater than the maximum motor current to ensure reliable and safe operation. Ideally, opting for an ESC with a continuous current rating higher than the maximum motor current is advantageous. This surplus capacity provides an additional safety margin, contributing to the longevity and reliability of the drone's propulsion system. This ensures the ESC can handle unexpected spikes in current demand, preventing overheating and potential damage. Drone motors are labeled with N & P ratings, such as 12N15P, indicating the number of poles in the motor stator and the permanent magnets. Fewer poles, as seen in 12N15P, result in higher torque, while more poles contribute to smoother operation due to a uniform magnetic field. As drone motors are three-phase, pole numbers are always multiples of 3. For 22XX and 23XX BLDC motors, the common configuration is 12N15P. It's important to note that the number of poles and magnets doesn't directly impact motor performance but is essential for configuring flight controllers, like enabling RPM filters. Understanding these ratings ensures optimal performance and responsiveness in drone systems. Drone motors, specifically the 22XX, 23XX, and 24XX series, feature versatile mounting patterns of 16x16mm or 16x19mm. To ensure compatibility with various frames, a drone frame must support both of these patterns. For the attachment of these motors, M3 screws are the standard choice. The key consideration here is the length of these screws, which should exceed the thickness of the drone arm by 2mm. For example, if the drone arm is 5mm thick, the recommended length for the M3 screws is 7mm. This precision in screw length is crucial for a secure and stable connection between the motors and the frame. Following these guidelines ensures a reliable and robust assembly, contributing to the overall performance and structural integrity of the drone. The choice of motor winding significantly influences motor performance. Thick wires handle higher currents but reduce the electromagnetic field, impacting torque. Thin wires excel in creating strong electromagnetic fields and torque but struggle with high current draw due to increased internal resistance. To navigate this balance, manufacturers often opt for thick copper wires with more windings. This combination maintains current resilience while enhancing the stator's electromagnetic field, resulting in increased torque. Motor windings come in two options: single-stranded and multi-stranded. Single-stranded uses thick wires for larger current draw, suitable for high-voltage battery packs. Multi-stranded, with three thinner strands, produces powerful electromagnetic fields and torque but faces a risk of damage from high current draw, leading to a lower KV rating. The motor's bearing size directly influences its durability and operational smoothness. Larger bearings enhance durability by distributing loads and dissipating heat effectively, making them suitable for heavy-duty applications. On the other hand, smaller bearings contribute to stability and smooth operation, ideal for precision machinery. The inner diameter of the bearing determines the motor shaft size, emphasizing the interconnected nature of motor components. Some manufacturers promote motors with ceramic bearings for their smooth performance, though they may be more prone to breakage compared to steel bearings. Drone motors rotate in opposite directions for stability during flight. If all motors spun the same way, the drone would struggle to lift off and maintain control. To achieve balance, motors mounted diagonally across from each other rotate in opposite directions—one clockwise, the other counter-clockwise. This configuration counters torque, ensuring a stable and controlled flight, a crucial design principle adopted in multirotor drones for optimal performance. Drone motors, categorized as brushed DC or brushless DC, dictate the rotation direction — clockwise or counterclockwise. Brushed motors have two wires, while brushless ones have three, all connecting to the Electronic Speed Controller (ESC), which, in turn, links to the flight controller. Brushless DC motor with ESC. Source from tytorobotics.com Swapping any two wires connected to the ESC reverses motor rotation. This simple adjustment is instrumental in tailoring the drone's behavior to specific flight conditions or preferences. Additionally, the flight controller, responsible for stability and orientation, can be programmed to further modify motor behavior, providing a centralized and efficient means of control. The choice of motor technology for heavy lift drones plays a pivotal role in determining performance, efficiency, and overall reliability. Each type of motor has its advantages and disadvantages. Let's briefly discuss each type: Brushed DC motors rely on a mechanical system involving brushes and a commutator to transfer current, whereas AC and brushless DC motors utilize electronic mechanisms. Brushed motors have a wound armature connected to a central permanent magnet, and as the brushes contact the commutator, current flows through the armature coils. In contrast, AC and BLDC motors pass current through the stator, eliminating the need for mechanical brushes. AC induction motors induce rotation in the rotor through a rotating magnetic field in the stator, while BLDC motors, with permanent magnets directly bonded to the rotor, generate motion as the stator produces electromagnetic poles. The construction differences contribute to varied performance characteristics. Brushed vs. brushless DC motor. Source from ato.com JIANGMEN PRO-TAYLOR REFRIGERATION CO., LTD. , https://www.protaylor.comWhat is a Heavy Lift Drone Motor?

What Types of Motors are Used in Heavy Lift Drones?

Brushless DC Motors

Counter-Rotating Drone Motors

What to Consider When Choosing the Best Heavy Lift Drone Motors?

Drone Weight & Frame

Thrust to Weight Ratio

Motor Size

Wider Motors

KV Rating

Motor Torque

KV vs. Torque Constant

Current Voltage & Efficiency

N & P in Motor

Mounting Pattern

Motor Winding

Motor Bearing

Motor Movements

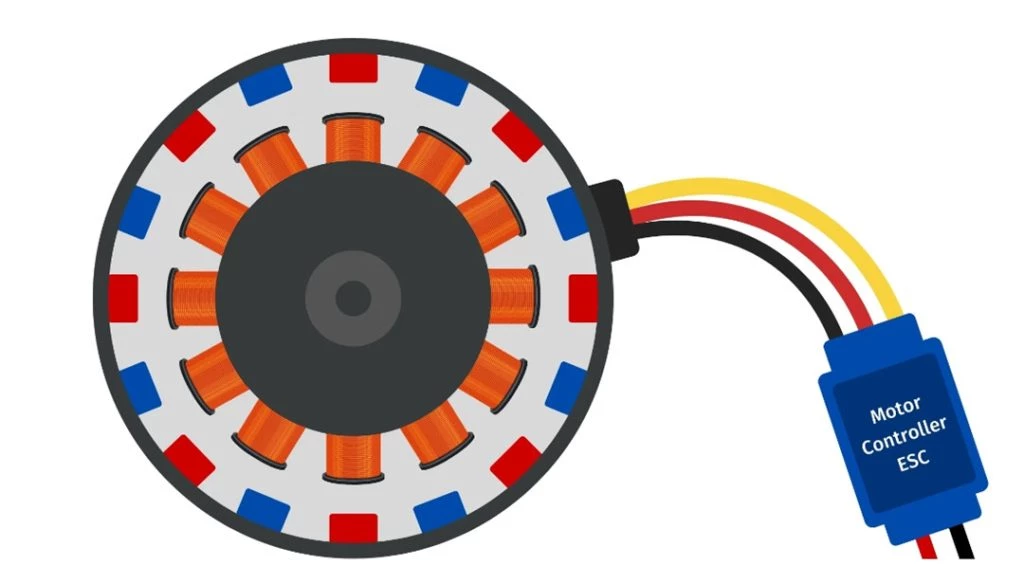

Motor Connections

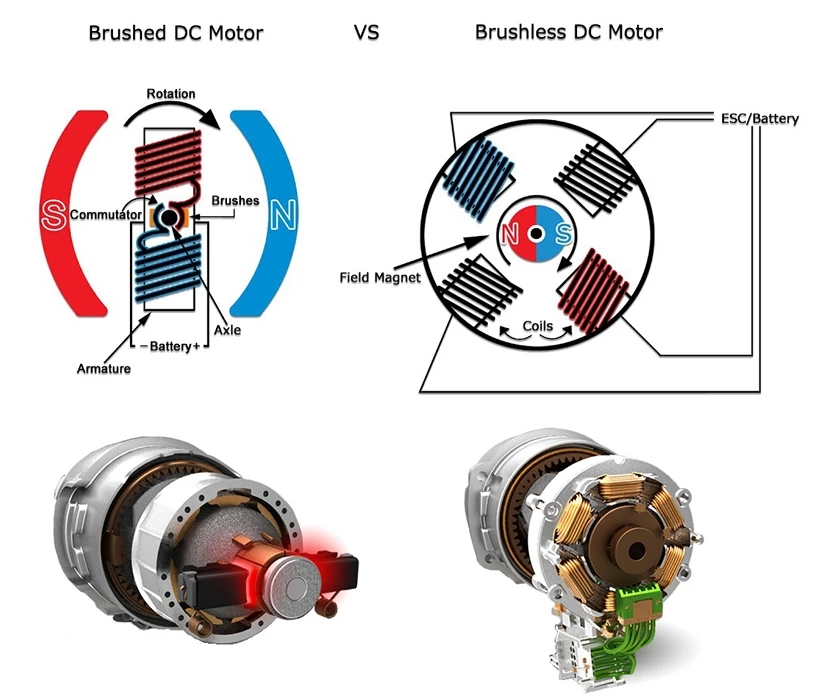

Brushless DC Motor vs. AC Motor vs. Brushed Motor

Motor Construction

Juice Dispenser