Crawler excavator Professional crawler excavator manufacturer

Rhinoceros crawler excavator series : 0.8T XN08,1.2T XN12 ,1.6T XN16,1.8T XN18,2T XN20,2.5T XN25,3.5T XN35,4.5T XN45,6.8T XN80-E

Here are main information of 6.8 Ton crawler excavator:

Crawler excavator XN80-E picture:

Rhinoceros excavator manufacturer here, our brand is Rhinoceros/ XINIU. We can ship internationally to almost all over the world. We calue our customers and take pride in delivering a fast and friendly service with the aim of seeking long term trading relationships. Please feel free to contact us for further information.

Email: sales4@sdxiniu.com Contact: Ms. Jessie Du

whatsapp:+86-18769517398

wechat:13375605858

Crawler Excavator,Crawler Excavator Road Construction,Crawler Excavator For Sale,Wheel Crawler Excavator SHANDONG KEN STONE HEAVY MACHINERY CO.,LTD , https://www.chinaexcavator.com

Model

XINIU XN80-E

Engine

YANMAR

POWER

44kw/2200rpm

Emission

Euro 3

Bucket capacity

0.3cbm

Operation weight

7000kg

Dimension

5830x2150x2640mm

Max. digging height

6320mm

Max. digging depth

3840mm

If your company relies on traditional baffled bags and you're looking to improve sustainability while reducing costs, it might be worth exploring some newer FIBC solutions that offer both eco-friendly advantages and long-term financial savings. The Hyperbolicâ„¢ baffle bag technology is revolutionizing the way we store and transport goods by introducing a fresh and innovative approach. Say goodbye to unnecessary internal seams and hello to increased efficiency and stability. Are you ready to learn more? Chat live now to discover how these bags can benefit your business.

---

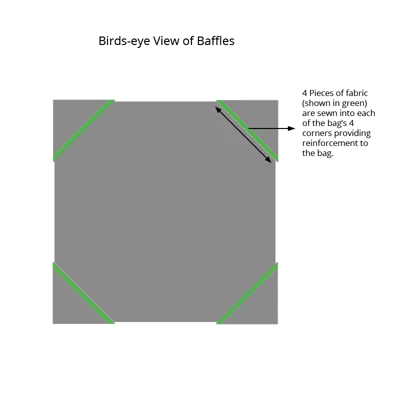

So, what exactly is a baffle bag? For those new to the world of bulk storage, a baffle bag is a type of FIBC (Flexible Intermediate Bulk Container) designed to maintain a square shape when filled. This design optimizes storage and transportation efficiency. Traditional baffle bags include additional internal fabric panels sewn into each corner to preserve the square shape.

Looking for regular updates? Fill out the “Subscribe to our blog updates†form to stay informed.

---

### Applications for Baffled FIBC Bulk Bags

Baffled FIBC bags are perfect for storing and transporting dry, free-flowing products. They work well for items such as:

- Blended feed

- Chemicals

- Corn

- Dry beans

- Flour

- Fumed silica

- Grains

- Mineral supplements

- Peas

- Pet food

- Petrochemicals

- Resin/plastic materials

- Rice

- Sand

- Seeds

- Sugar

- Soybeans

- Wheat

However, they are not ideal for large, bulky materials that don’t flow smoothly. These materials can get stuck in the internal baffles, making it difficult for the bag to expand fully, which can lead to stability issues.

If you're curious whether standard FIBC bulk bags with baffles are right for you, check out more details on Standard FIBC Bulk Bags with Baffles.

---

### Introducing Hyperbolicâ„¢ Technology

The Hyperbolic™ baffle bags eliminate the need for internal baffles by using a specially woven fabric. This innovation effectively manages outward forces, maintaining the bag’s shape without the need for extra seams. Some key features of this new bag include:

- **20% Less Manpower in Manufacturing & 23% Less Material Consumption**: Cost-effective and environmentally friendly.

- **Zero Vertical Seams**: A smooth, seamless design makes handling easier.

- **30% Storage Optimization**: Significant space savings compared to traditional FIBCs.

---

### Why Choose Hyperbolicâ„¢ Baffle Bags?

- **Cost Efficiency**: Reduced stitching and material usage lead to cost savings for you.

- **Eco-Friendly**: Lower polymer consumption supports sustainable practices.

- **Enhanced Stability**: The unique design ensures excellent stability and stackability, essential for safe storage.

---

### Common Questions Answered

**Q: How do Hyperbolicâ„¢ bags enhance stability?**

A: The absence of internal seams allows the structure to distribute forces evenly, maintaining the shape effortlessly and naturally.

**Q: Are these bags suitable for my industry?**

A: Yes, if your operations already use baffled bags or if you operate in an industry where they are beneficial, such as food and pharmaceuticals, where efficient storage is crucial.

**Q: Are Hyperbolicâ„¢ bags available to ship immediately?**

A: No, they are not a stocked option. Hyperbolicâ„¢ bags are custom-made to fit your specific operational needs. Click here to chat live with a Hyperbolicâ„¢ bag expert to determine if custom or stock options are best for your current requirements.

---

### Your Next Steps to Choosing the Right Bulk Bag

To explore current offerings, visit our page on **In-stock Baffled Bags**.

With new technology and standard baffled bulk bags still available, you can find the right bulk solution for your dry, free-flowing bulk products. Whether you’re dealing with grains or pharmaceuticals, these bags can meet your needs with utility, sustainability, and innovation in mind.

Interested in custom solutions? Request a custom bag quote or chat with a bulk bag expert to see how National Bulk Bag can tailor a solution for your business.

---

Thank you for reading!

We hope you found this article helpful and informative. Safety and reliability are our top priorities. Each bag available for purchase comes with a specific safe working load (SWL), commonly at 2,200lbs and 3,000lbs. To ensure the product you pack doesn’t exceed the SWL of the chosen bag, you’ll need to know the product’s bulk density and the cubic foot capacity of the FIBC.

Click the link below to download a helpful Product Weight Guide and FIBC Volume Calculator. These tools are designed to help you determine how much weight a specific bag can safely hold.

[DOWNLOAD THE GUIDE + CALCULATOR]

Thanks for visiting the National Bulk Bag blog! We appreciate your interest and look forward to assisting you further.